Add a Fighting Butt to a Fly Rod [How To]

Turn your regular fly rod into the ultimate Great Lakes steelheading rod with this simple modification. I’ve said in my previous posts on steelhead equipment that the perfect fly fishing rod is a 10’ 7wt fly rod. This is the perfect weight for our 20 to 30 inch steelhead, and at 10’ you can fish nearly every skinny riffle or wide pool found on the Great Lakes Tributaries. The downside of having an extra long rod is that they can be slightly more tip heavy.

The rod I decided to modify was a 10’ 7wt Redington Vice that is my dedicated steelhead rod. The Vice is a fantastic fast-action fly rod that, partly due to its 10’ length and durable build blanks, can be very tip heavy and can be tiring after a full day of steelheading. Adding a fighting butt to this rod has added a small amount of weight behind the reel, and it really helps balance out the rod.

In addition to creating a better balance, adding a fighting butt to your fly rod can greatly improve its versatility and allow you to easily switch to a shooting head system, allowing you to make a multitude of two-handed spey casts to throw streamers, as well as give you extra power to throw those big double-fly nymph rigs upstream. You will be able to make giant mends in order to obtain a drag-free drift in the toughest of water currents. And if that isn’t enough, having an extended handle will give you more leverage when fighting that fish of a lifetime.

This is also a great modification for a 9-11wt musky rod, allowing you to anchor the extended fighting butt into your forearm for increased casting power when throwing those bulky doubles, as well as giving you more leverage when you figure-8 your fly at the boat.

Disclaimer: Modifying your fly rod will void the warranty of your fly rod. Modify your fly rod at your own risk.

I would not recommend this on a high-end fly rod, especially if you are planning on sending in your rod for any warranty repair. There is obviously a small amount of risk when modifying your fly rod. Changing the leverage point on a high modulus fly rod can cause the bending point under load to shift, causing your rod to break. Modify at your own risk.

If you are aware of the benefits and risks and ready to get started building a more useful fly rod, then let’s get started!

What You’ll Need

- Fly Rod

- 5 minute Epoxy

- Painters Tape

- Cork

- Old Fishing Rod Blank, or small metal rod

- Sandpaper

- Utility Knife

- Drill

1: Make the Handle

You have a couple of options for materials when making your fighting butt. For this project I cut off the end of an old broken shore rod, but you can also glue individual cork rings and an end cap together to get the same result.

2: Sand the Handle to Shape

Use a standard drill to sand your handle to shape. Wrap painters tape around a drill bit until it fits snugly inside the cork.

The benefit of doing this yourself is that you get to decide the exact handle shape and length that you want. I made this fighting butt 2.25” long and shaped it to be thicker at the end with a slight bulge towards the reel seat for a better grip and easier two-handed casting.

Start with a coarse 60-100 grit sandpaper to make the initial shape of the handle. Then step down to a 150 or finer for the finishing touches.

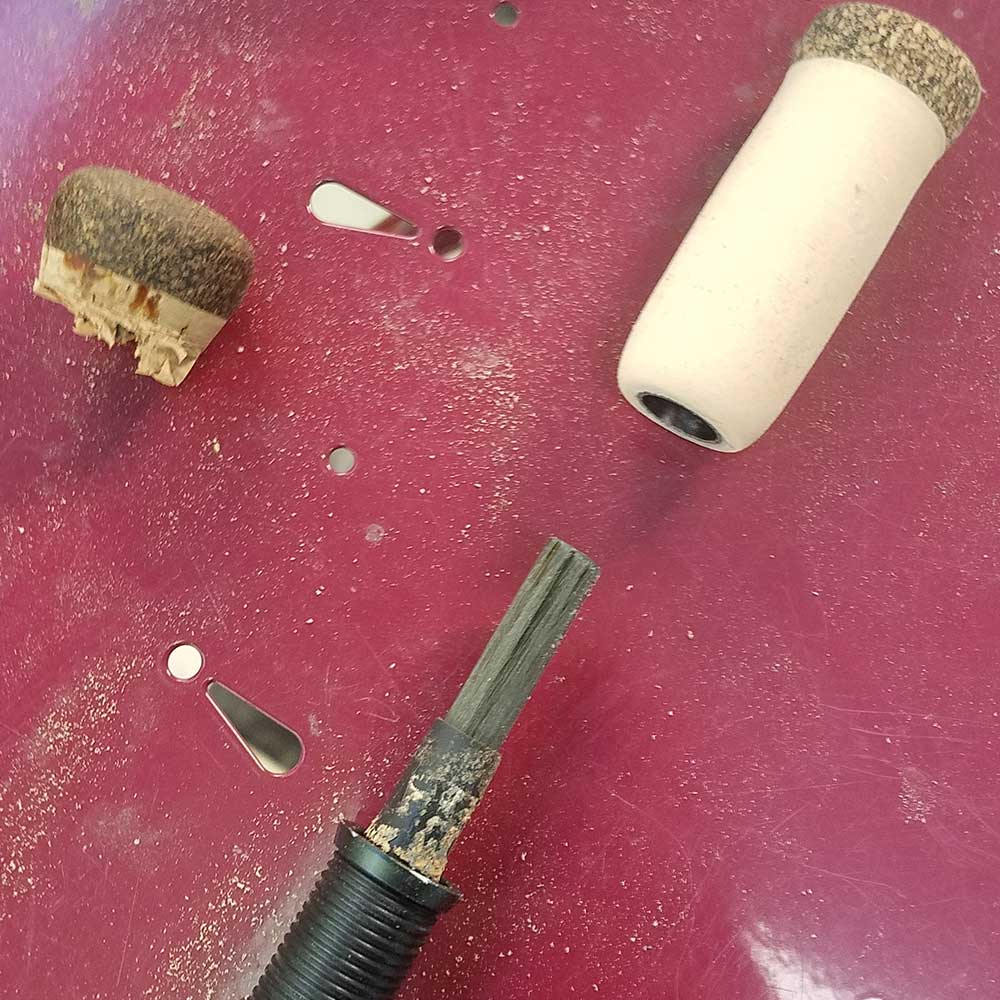

You can see the old 3/4” fighting butt that came on my Redington Vice next to the new fighting butt that we are going to put on this rod.

4: Remove the Old Fighting Butt and Prepare the Extention

This is the scariest part of the process. Cutting the cork fighting butt off of your rod. If your rod already has a small fighting butt then the rod blank will extend past the reel seat. You can either cut the blank off flush, but I would recommend simply cutting the old cork away from the blank.

In order to add structure and rigidity to the handle, you will need to extend the current blank so it extends into your longer fighting butt. Use a section of an old rod blank or buy a cheap or broken blank at a local rod building supplier. You will want a section that is small enough to fit inside the rod blank, but as large as possible to maintain rigidity.

If your rod blank is too small to fit snugly, you can wrap painters tape around the blank until it fits snugly into the rod’s blank.

5: Mix Your Glue

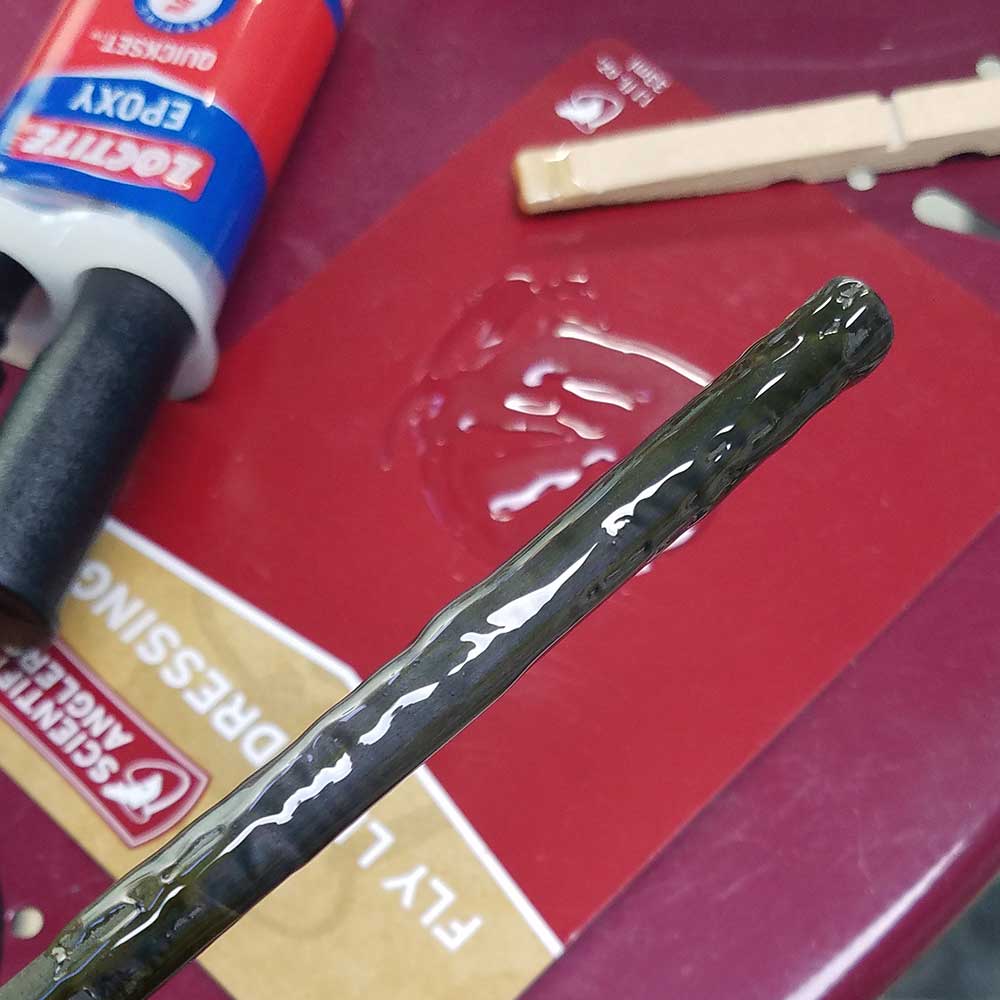

Mix up some two-part epoxy and coat the section of rod blank.

6: Test the Fit

Insert the blank into the end of your rod. Make sure that the new handle will fit over the new extended rod blank and will allow for a flush fit against the reel seat.

7: Add Tape to Make a Snug Fit

Wrap painters tape around new extended blank to build it up in order to fit snuggly into the new fighting butt.

8: Glue the New Fighting Butt onto Your Fishing Rod

Mix up another batch of two-part epoxy and coat the new rod blank and painters tape. Slide your new fighting butt onto your rod and apply firm pressure. Epoxy will get pushed out from between the fighting butt and your reel seat. Make sure you wipe any epoxy off the threads and fighting butt. As an extra precaution you can put painters tape over your reel seat and fighting butt.

9: Admire Your Work and Go Fishing

You’re done! Admire your work and hit the water with your new workhorse of a fly rod!

Share with a friend!

js-outdoors is a free resource for all.

Please consinder donating to keep this site ad-free!

![How To Tie An Intruder [video]](/images/how-to-tie-an-intruder.jpg)

![Steelhead In The Snow [video]](/images/steelhead-in-the-snow.jpg)